- cross-posted to:

- hackernews@lemmy.smeargle.fans

- cross-posted to:

- hackernews@lemmy.smeargle.fans

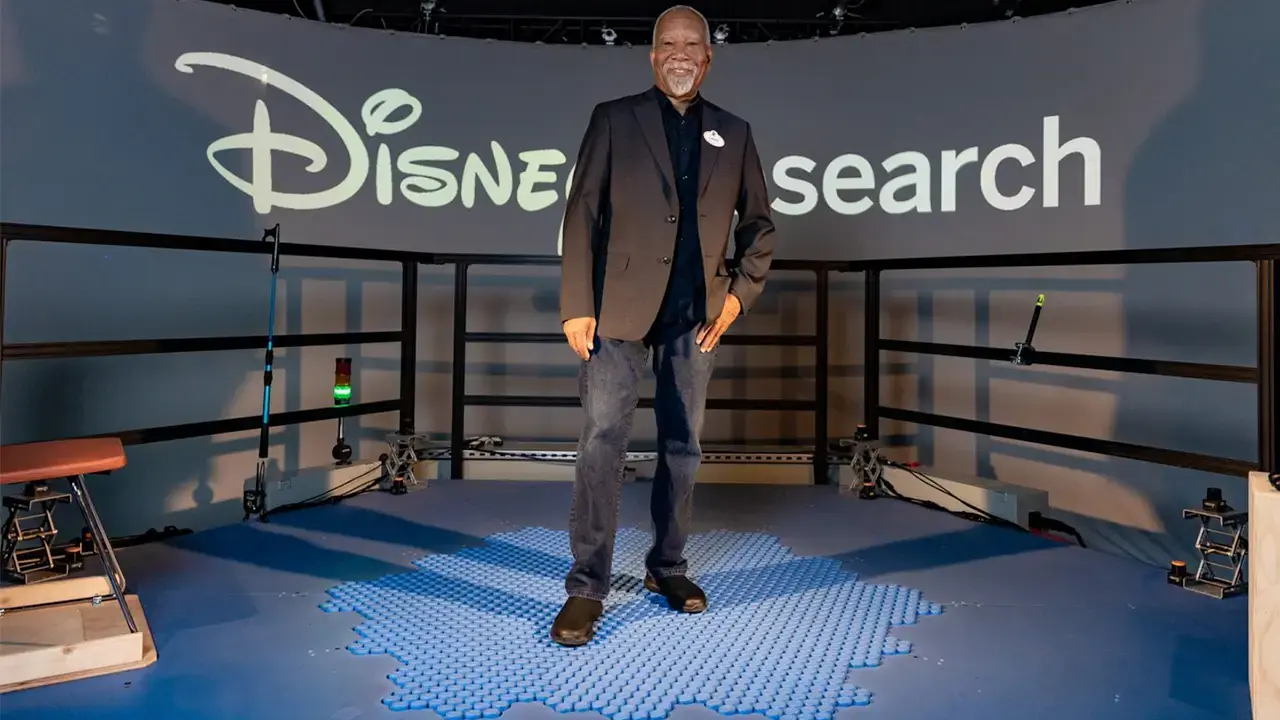

This technology looks legitimately impressive.

Here’s a video of it working: https://www.youtube.com/watch?v=m3Sh6mu4zbs&t=1

This thing is so technically complex and has so many moving parts that I can only imagine it breaking literally constantly and costing a fortune to repair whenever it does.

So, a Disneyland ride?

I can only assume the reason you’d work for Disney as either an engineer or technician is if you have a kink involving being in a constant and inescapable state of overworked frustration.

Depending on how exactly is it made, it could have fewer moving parts than it looks like. The tilt seems to be controlled on a whole module at a time level, and I’m guessing all the tops of a module might be rotating in the same direction. That would still leave a lot of linkages and bushings or bearings, but make it easily serviceable by just replacing them. The modular design seems to indicate you could pick a whole hexagon tile, replace it with a working one, and service the damaged one in the background.

That’s fucking rad. The best implementation of an omni-treadmill I’ve seen.

Yeah it’s pretty neat. You can also imagine a version that goes 3D, maybe replicating uneven ground or stairs.

Going 3D would require variable size tops, variable heights, more tilt, and more granular control. Doesn’t seem like this design would allow any of those. It’s still cool, but is no solid light yet 😉

Good job imagining a version that could go 3D

just make housing and food less expensive its all we ask

But this way, you can have virtual housing and food!

This problem had already been solved https://i.makeagif.com/media/3-03-2015/at5UtW.gif

And Jesus wept!

So, that was a passive tech, keeping you in a place, and this actively works to steer you to where you need to be. This seems better in the long run for that purpose even though it’s much more complicated.

Oh, I agree. I’m duly impressed. It’s just that I immediately thought back to that scene from community. I’m not good about remembering to call out my sarcasm.

Unfortunately inertia presents a problem it’s the same with omnidirectional treadmills. https://youtu.be/fvu5FxKuqdQ

I was fully expecting to see this https://www.youtube.com/watch?v=4JkIs37a2JE

I’ve seen another video where the guy stops moving on it and you can immediately see the problem this and any other tech like this has: momentum. It just can’t stop/start fast enough.

It’s only a first version. I’m sure with time, it’ll get even better.

I’m looking forward to this. Combine it with eye-tracking 3D and you’ve got everything except the tactile response for a holodeck. Like this: https://youtu.be/Jd3-eiid-Uw

Woah cool!

really a cool tech, cant imagine how it would work. Could definitely make walking in VR a lot less cumbersome.

It will make VR even more fun so I am looking forward to it

That’s so cool how is he so causal about all of that. It looks like one day it will be able to handle running jumping and all kinds of movement. Vr is going to be better than real life.

Real life sucks so that’s a low bar for VR to surpass.

Whoa what the fuck? How does it even work? It looked like you can control the direction the floor itself is moving the things on it (the way they are “force pushing” the box or when the old guy is in the chair) but it also looked like it wasn’t even moving, or uses power.

This shit looks like magic.

Seems to be a lot of cylindrical pillars with pressure sensors and motors, that can be tilted by a slight degree in both X-Y axes, or they have a fixed tilt and just the tilt direction is rotated in Z (seems like the pillars of a whole module get adjusted all at once), making only some borders be in contact with an object. A program can track the position of an object, then calculate how to tilt and rotate the pillars so the borders in contact with the object will push it in the desired direction.

It reminds me somewhat of an omniwheel control system, but applied to the floor instead of the wheels.

Is it just me or does it seem 3d printed? How cool would it be to just 3d print a playspace like this

The spinning tops might be 3D printed, but there are some motors and pressure sensors involved, plus some electronics, and you probably want a steel plate underneath holding it all together. Tolerances would also be quite tight.